1.laser cutting, 30 times faster than mechanical methods

In the industry with laser cutting materials are: alloy, nickel alloy, chromium alloy, aluminum alloy, stainless steel, acid key, plastic and composite materials.

In the manufacture of the equipment, the Shell is made of special metal material, which has high strength, high hardness and high temperature resistance. It is difficult to finish the material processing by common cutting means. Laser cutting is an efficient processing means, can Be used for laser cutting aircraft skin, honeycomb structure, frame, Wing Bin, tail avoid plate, helicopter main rotor, engine casing and Flame Tube, etc. .

Laser cutting generally used continuous output laser, there are high repetition rate of carbon dioxide pulse laser. The depth-to-width ratio of laser cutting is high, for non-metal, the depth-to-width ratio can reach more than 100, the metal can reach about 20. Laser cutting speed is high, cutting Chin Alloy Sheet is 30 times of mechanical method, Cutting Steel Sheet is 20 times of mechanical method.

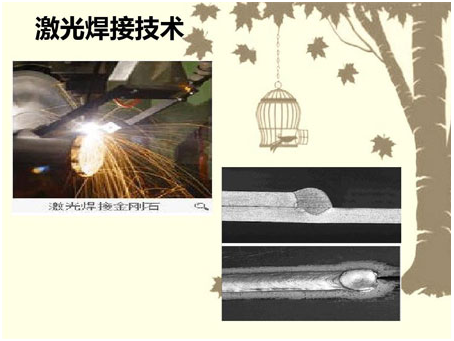

2. Simplify the manufacturing process of the airframe by laser welding

In industry, many parts are Electron beam welding, and laser welding is being used instead of Electron beam welding because it is not required in a vacuum.

For a long time, the connection between the aircraft structure parts has been using backward riveting technology, mainly because the aircraft structure using aluminum alloy material is heat treatment strengthened aluminum alloy (that is, high-strength aluminum alloy) , once welded, the strengthening effect of heat treatment will be lost, and the intergranular crack is hard to avoid.

And the use of laser welding technology, to overcome such difficulties, but also greatly simplified the aircraft body manufacturing process, so that the weight of the aircraft body reduced by 18% , cost reduction of 21.4%-24.3% , laser welding technology is a technical revolution in aircraft manufacturing industry.

3.Laser drilling technology helps to reduce cost and increase efficiency

LASER DRILLING TECHNOLOGY IN INDUSTRY IS APPLICABLE TO INSTRUMENT GEM bearings, air-cooled Turbine Blades, nozzles and combustion chamber on the drilling.

At present, in machining engine parts, laser drilling is limited to machining cooling holes of engine static parts, because there are micro-cracks on the surface of the holes.

The experiments of laser beam, electron beam, electrochemistry, electric spark drilling, mechanical drilling and punching have been carried out. Laser drilling has the advantages of good effect, strong universality, high efficiency and low cost.

This shows that the future market potential of laser unlimited, the country’s heavy manufacturing equipment for laser equipment requirements are also changing.

Copyright©2021 青岛致远数控设备有限公司鲁ICP备155455号-1 Technical Support:Huaxia